TEA@SUNRISE is aiming to use next-generation solar to support a just, equitable, and sustainable energy transition. But what is next-generation solar? And why are we focused on these newer technologies over traditional, silicon solar?

What is next-generation solar?

Put simply, next-generation solar is any un-commercialised but potentially transformative solar energy technology. It could address problems faced by current technologies, such as with cost, efficiency, and manufacturing.

Crystalline silicon photovoltaics (PV), the typical panels you might see on people’s houses, are first-generation solar. These panels currently dominate the market at 94%. Second-generation solar is made up of thin-film technologies that use less material, such as cadmium telluride (CdTe) and copper indium gallium selenide (CIGS). These technologies account for a bout 6% of the global market. Next-generation solar includes a range of new materials and designs that are not yet on the market, such as organic and perovskite PV.

What are perovskite solar cells?

One next-generation solar technology that gets a lot of attention is perovskite PV. These solar cells use a material called perovskite as a light-absorber. Perovskites show great promise as a high-performance but low-cost technology.

Oxford PV, one of the world leaders in perovskites, makes high efficiency cells by combining silicon and perovskite. These perovskite-on-silicon ‘tandem’ solar cells hold the world-record efficiency for a solar module at 26.9%. In September 2024, Oxford PV sent their first commercial panels to a US-based customer.

Several Chinese companies are relatively advanced with manufacturing perovskite-only (single-junction) PV. MicroQuanta exhibited coloured and transparent modules at Intersolar 2025 in Munich and has deployed these at many demonstration sites in China.

What is organic PV?

Organic PV (OPV) uses organic electronics to generate electricity. Organic electronic materials are made from carbon-based molecules or polymers. These solar cells are cheap to manufacture, can be flexible and transparent, and work well under low-light conditions. They have been shown to work well for indoor and agrivoltaic applications.

Heliatek produces OPV modules for building integration at its factory in Germany. The company has installed over 75 systems to date. Their modules have achieved IEC certification with stated lifetimes of 20 years. Although lower efficiency than silicon or perovskite, the company claims that the modules’ low embodied energy leads to very short energy payback times.

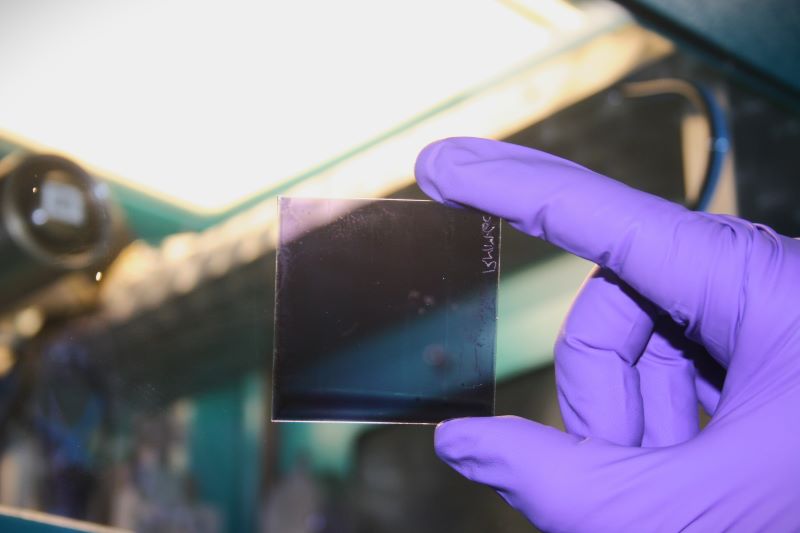

Right: Example of a transparent organic solar cell. Credit: ATIP at Swansea University.

Why use next-generation solar for a just energy transition?

Next-generation solar technologies have a few advantages when it comes to securing a just energy transition. For instance, silicon PV manufacturing is energy-intensive and needs a hefty upfront investment. It also uses a considerable amount of critical materials. But next-generation technologies, such as perovskites, are generally simpler to manufacture. They also have the potential to be lower cost, use fewer critical materials, and be more efficient compared to silicon.

We also believe that these newer technologies could bring PV manufacturing much closer to where it is needed. Solar is largely not manufactured in low- and middle-income countries. In fact, 80% of all solar modules are produced in China. Chinese-manufactured modules are difficult to separate from a range of ethical and environmental issues, including the possibility of forced labour and use of cheap electricity from coal combustion.

Africa has around 600 million people without electricity and abundant sunshine. Solar energy is an obvious solution. Presently, solar modules are either imported or assembled in Africa, but not manufactured on the continent. Local manufacturing could reduce logistics costs, create jobs, and use lower-carbon sources of energy. What’s more, technologies could be tailored to suit local contexts, communities, and geographies.

Since it is in the early stage of development, next-generation solar also offers a unique opportunity to be designed for sustainability. We can design them to be easy to re-use and re-manufacture from the outset, minimising waste and retaining valuable materials.

What are the challenges facing commercialisation of next-generation solar?

As with any new technology, there are of course challenges to overcome. Primarily, we need to translate the efficiency and stability achieved in the lab to commercial-scale modules. To be commercially viable, they must prove they have sufficient lifetimes and power outputs to justify the financial cost of making them. For solar to continue addressing the climate crisis, they need to offset more carbon emissions than are associated with their manufacture. If they cost more money or produce more emissions than they would save in their lifetimes, then they are not an effective technology.

Scaling-up next-generation solar is another challenge. The lab-based processes used to make high-performing devices often don’t work at scale. So you can’t just make the lab equipment bigger – often you need to apply a distinct process when fabricating the modules at scale. To make modules at commercial rates, these processes must be fast and reliable over large areas. A solar module will only perform as well as its worst performing cell, so reliable processes that produce minimal defects are crucial.

Supply chains and materials are also potential obstacles. Some of the chemicals needed to make next-generation solar are not currently manufactured at scale. And many perovskite devices contain materials like caesium, indium, and gold, which are not readily available. Hypothetically, to produce a terawatt-scale output from next-generation PV using these materials, you would need a projected production increase of over 1000% in some cases.

However, progress is being made on all of these challenges. Small perovskite modules have achieved 19.5% efficiency, up from 5.1% in 2014. Chinese company WonderSolar has set up a 110 m2 perovskite PV system which has been continuously generating electricity since its implementation in 2018. And Oxford PV has tandem perovskite-silicon panels on the market at 24.5% efficiency.

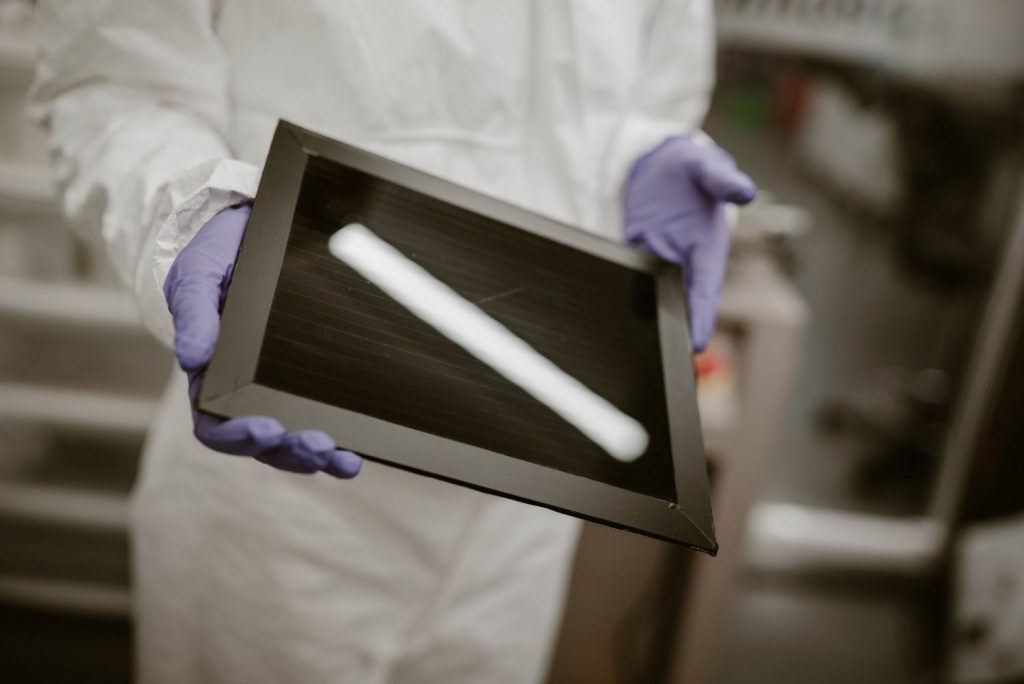

Researchers at Swansea University are finding ways to take next-generation solar devices from the lab to building scale. They use techniques that are easily scaled-up, such as screen-printing and mechanical scribing.

It is also possible to swap many of the critical materials used in perovskite solar cells with more readily-available ones. And where substitution isn’t possible, there are methods to retain valuable materials via recycling and remanufacture.

What’s next?

At TEA@SUNRISE, we are seeking ways to implement next-generation solar technologies in collaboration with low and middle income countries.

Professor Emeka Oguzie and his team at ACE-FUELS (African Centre of Excellence in Future Energies and Electrochemical Systems) are planning to produce the first perovskite solar module in Africa by March 2026. Demonstrating this module will be an important step towards commercial manufacturing. Emeka, who is a member of the TEA@SUNRISE network, believes it would be a big boost to the solar industry in Nigeria:

“It is absolutely possible for us to manufacture perovskite solar cells in Nigeria. The conditions needed for manufacturing perovskites are less technically demanding than for silicon. Most importantly, having this first demonstration of a perovskite module will give us the opportunity to play and experiment with the technology. I think it will attract more people to work on it, especially young people. Young people in Nigeria are very tech-savvy. So the potential for rapid growth and innovation is there.”

Related to TEA@SUNRISE, the REACH-PSM project is supporting the local manufacture of perovskite solar modules in Nigeria, Rwanda, Kenya, and South Africa. The project hopes to empower communities in Africa by fostering energy independence and creating jobs. In the process, it will set a new standard for sustainable energy solutions.

Next-generation solar can play a vital role in delivering an equitable and just energy transition. A lower-cost, simpler, and more sustainable technology compared to silicon, it can also be more easily adapted for local contexts. While there are challenges to overcome, these newer technologies could be transformative for tackling energy access.

If you’d like to contribute to a global effort to address energy access through next-generation solar, join the TEA@SUNRISE network.

Right: Members of the TEA@SUNRISE network at our symposium in Durban, South Africa in January 2025.

Thanks to Dr Mark Spratt and Dr Carys Worsley for their contributions to this blog.

TEA@SUNRISE is part of the Transforming Energy Access platform funded by UK aid from the UK Government to support the technologies, business models and skills needed to enable an inclusive, clean energy transition.